Exploring the Future of Precision Cutting: Our Laboratory Wire Cutting Equipment Series

Table of Contents

What is The Laboratory Cutting Machine

The Laboratory Cutting Machine is a precision instrument that is used to cut various types of materials, specimens, or samples for research, experimentation, and testing purposes. These machines are commonly found in research laboratories, quality control facilities, and testing centers across a wide range of disciplines, including materials science, biology, chemistry, engineering, and more.

Laboratory Cutting Machines are designed to ensure consistency in sample preparation, which is crucial for obtaining reliable and repeatable research results. They are also used to create precise cuts that are necessary for certain types of experiments and testing procedures.

Description

In today’s rapidly developing fields of scientific research and materials engineering, laboratory cutting equipment plays a crucial role. They are not just tools, but engines driving innovation, helping researchers precisely process various complex materials. As a leading company focused on precision cutting technology, we proudly introduce three wire cutting equipment models specially designed for laboratories: SGD52, SG15, and SGR15. These devices adopt an advanced gantry structure, ensuring stability and precision, suitable for scenarios ranging from basic experiments to high-end scientific research. Whether in materials science, semiconductor R&D, or biomedical applications, our equipment provides reliable support. Below, let’s delve into the unique advantages, core functions, and wide applications of these devices, and explore how our customization services can meet your personalized needs.

Core Design Philosophy: Precision, Simplicity, and Adaptability

Our three laboratory wire cutting equipment models share a common design philosophy: user-centered, ensuring simple and efficient operation. All devices use a gantry cutting structure, which resembles a sturdy “portal,” providing excellent rigidity and stability. The cutting wire is parallel to the horizontal plane, performing cuts from top to bottom, which not only reduces gravity interference but also achieves more uniform force distribution. The core cutting medium is annular diamond wire—a highly wear-resistant and corrosion-resistant closed-loop wire material that maintains sharpness during high-speed operation, ensuring a smooth cutting process without burrs.

In addition, the fixture design of these devices is one of our highlights. We understand the diversity of laboratory workpiece shapes and materials (such as cylindrical crystals, irregular ceramics, or thin metal sheets), so we have developed a modular and adjustable fixture system. It supports quick fixation and release, accommodating multiple materials (such as silicon wafers, glass, or composites). This greatly reduces operational risks and avoids common workpiece displacement issues in traditional equipment. Overall, these devices cover a gradient of functions from simple to complex, helping laboratories of different scales work efficiently—small laboratories can choose the basic model, while large research institutions can opt for the advanced version.

Detailed Overview of the 3 Laboratory Cutting Machine

1. SGD52: Entry-Level Precision Cutting Expert

The SGD52 is the entry-level model in our series, designed specifically for budget-constrained or beginner laboratories. It provides basic wire cutting functions with cutting precision down to the micron level, suitable for handling small to medium-sized workpieces (such as samples with a diameter of no more than 50mm). The advantage lies in its minimalist operation interface: just a few steps to set parameters, and the cutting process can start without professional training. The application of annular diamond wire ensures efficient cutting, while the device has built-in safety sensors that can automatically stop to prevent accidents.

Advantages: High cost-effectiveness, simple maintenance, and low energy consumption. Compared to traditional saw blade cutting, the SGD52’s diamond wire reduces material waste and improves cutting efficiency by over 30%.

Applications: Widely used in university laboratories for material preparation, prototype testing, or geological sample cutting. For example, in materials science experiments, it can precisely cut silicon wafers for microscope observation; in environmental science, it can process rock samples for composition analysis.

2. SG15: Versatile Balanced Choice

The SG15 is positioned as a mid-range model, balancing functionality and ease of use. It builds on the SGD52 by adding an automatic feed system and programmable control, supporting more complex cutting paths (such as curves or multi-layer cuts). The cutting wire speed is adjustable to adapt to different hardness materials, ensuring high surface finish quality.

Advantages: Strong flexibility, supports batch processing; integrated digital interface that can connect to a computer for data recording and analysis. This device particularly emphasizes user experience, with a touchscreen operation panel that reduces human error.

Applications: Suitable for R&D work in medium-sized laboratories, such as wafer cutting in the semiconductor industry or aviation material testing. In the biomedical field, it can be used for cutting tissue samples or implant prototypes; in nanotechnology, it helps prepare thin-film materials for electron microscope research.

3. SGR15: High-End Complex Task Conqueror

The SGR15 is the flagship model in the series, designed for high-end laboratory needs. It extends multi-axis motion control, supporting 3D path planning and real-time monitoring. The annular diamond wire, combined with an advanced cooling system, can handle high-hardness materials without thermal deformation.

Advantages: Extremely high precision, comprehensive functions, and strong scalability. Cutting efficiency is 50% higher than the entry-level model and reduces noise and vibration interference.

Applications: Suitable for large research institutions or industrial laboratories, such as precision optical component cutting, quantum material preparation, or aerospace alloy testing. In the pharmaceutical industry, it can cut drug crystals for structural analysis; in the new energy field, it helps process battery materials like lithium-ion electrodes.

The Advantages of This Endless Diamond Wire Saw Machine

1) High efficiency, Cutting speed is faster than bandsaw cutting machine

2) High precision, The tolerance of this machine is ±0.05 mm

3) Fully automatic, one person operation

4) less kerf loss compare to bandsaw

5) It cut all material no matter is conductive or not

6) Achieve smooth surface no matter it’s soft or hard or brittle material

Customization Services: Tailored for You

We understand that every laboratory’s needs are unique, so we offer comprehensive customization options. Whether adjusting the cutting wire length, adding specific fixture modules, or integrating dedicated software (such as CAD-compatible interfaces), our engineering team can respond quickly based on your specifications. In the past, we have customized equipment for many customers for special materials like silicon carbide or germanium glass, with delivery times as short as a few weeks.

The video shows the functions of SG15 laboratory cutting machine

Conclusion: Ushering in a New Era of Precision Cutting

Our SGD52, SG15, and SGR15 laboratory-cutting-machine series are not only reliable assistants in laboratories but also bridges to scientific breakthroughs. Through the gantry structure, annular diamond wire, and intelligent fixtures, these devices elevate precision cutting to new heights. If you are seeking reliable cutting solutions, we welcome you to contact us and explore how to integrate these innovations into your laboratory.

Perfectly Solve Your Cutting Problems

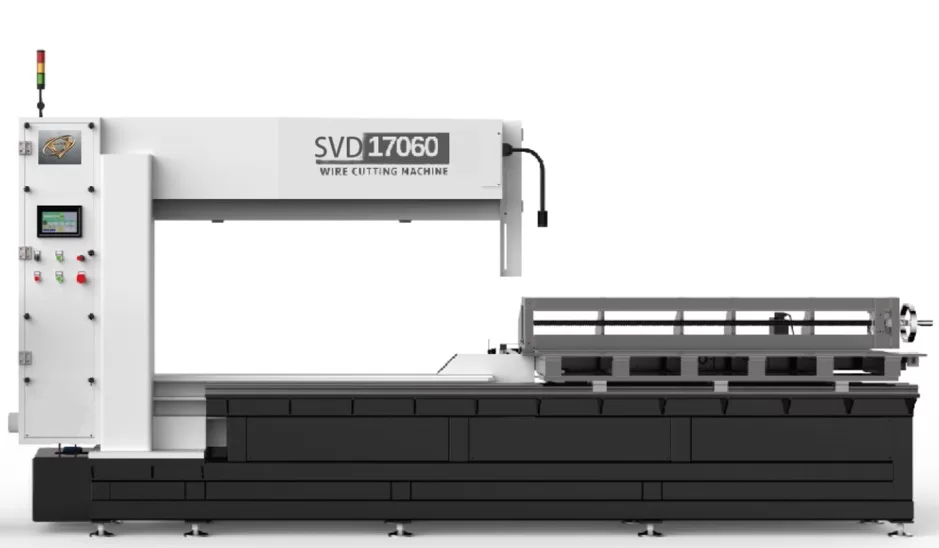

Vertical wirecutting machine can be adapted to all cutting scene with an satisfying performance

We accept sample cutting service, leave your information and enjoy our free cutting test service →

-1024x685.jpg)

Our Services

- Fast after-sales service

7 Days 24 Hours online

- Professional and experienced

Engineers have 5 years experience in this Industry

- High quality

Machine with International brands components and precision manufacturing

- Good Reputation

Shine Wirecut With high-quality products, stable use of effects, perfect, meticulous, fast after-sales service won the trust of customers

-1536x1024.jpg)

-1-1536x886.jpg)

.jpg)

-1024x683.jpg)

-1536x1024.jpg)

-1-1536x861.jpg)

-1024x683.jpg)

-1536x1024.jpg)

-1536x1024.jpg)

-1536x1024.jpg)

Sourcing Wire Cutting Machine From Vimfun Wire Cut

- For Factory Owners

We have worked with different companies to take their ideas from conception to realisation of their efficiency and a cutting solutions. Whether it’s a customised function or a customised look, we can provide you with the perfect processing solutions.

- For Distributors

Our modern production plant allows us to offer great quality options to appeal to your target customers. As a distributor you can trust that our streamlined manufacturing processes are here to provide you with the best machine in the market.

- For National Agents

Being one of the most famous endless diamond wire cutting Machine manufacturing companies, we offer the best quality products at a significantly low cost. This allows us to work with you to ensure that you get to also extend great prices to your customers.