The invisible precision technology behind the next generation of humanoid design.

1. The Rise of Ceramic Skeletons in Robotics

Humanoid robots are no longer distant science fiction. From factory assistants to social companions, their designs are rapidly evolving — and so are the materials that make them possible.

Unlike traditional metallic frames, the new generation of humanoid robots relies on advanced ceramics and composite materials to mimic the stiffness, lightness, and durability of the human skeletal system.

But ceramics, while strong, are notoriously difficult to process. Their hardness rivals that of sapphire or silicon carbide. Traditional machining leaves microcracks, uneven edges, and thermal stress — flaws that can compromise structural integrity and motion precision.

To build robots that move like humans, engineers needed a tool that could cut these materials with surgical accuracy and minimal damage. That tool turned out to be the Diamantdrahtsäge.

2. Precision at the Core: How Diamond Wire Cutting Works

Diamond wire cutting is not a new concept — it’s long been used in semiconductor wafering and sapphire processing. Yet, in robotics manufacturing, its role is just beginning to unfold.

A Diamantdraht is a continuous steel loop coated with micron-sized diamond abrasives. It moves at extremely high speed — often above 80 Meter pro Sekunde — slicing through hard materials with minimal pressure and almost no thermal deformation.

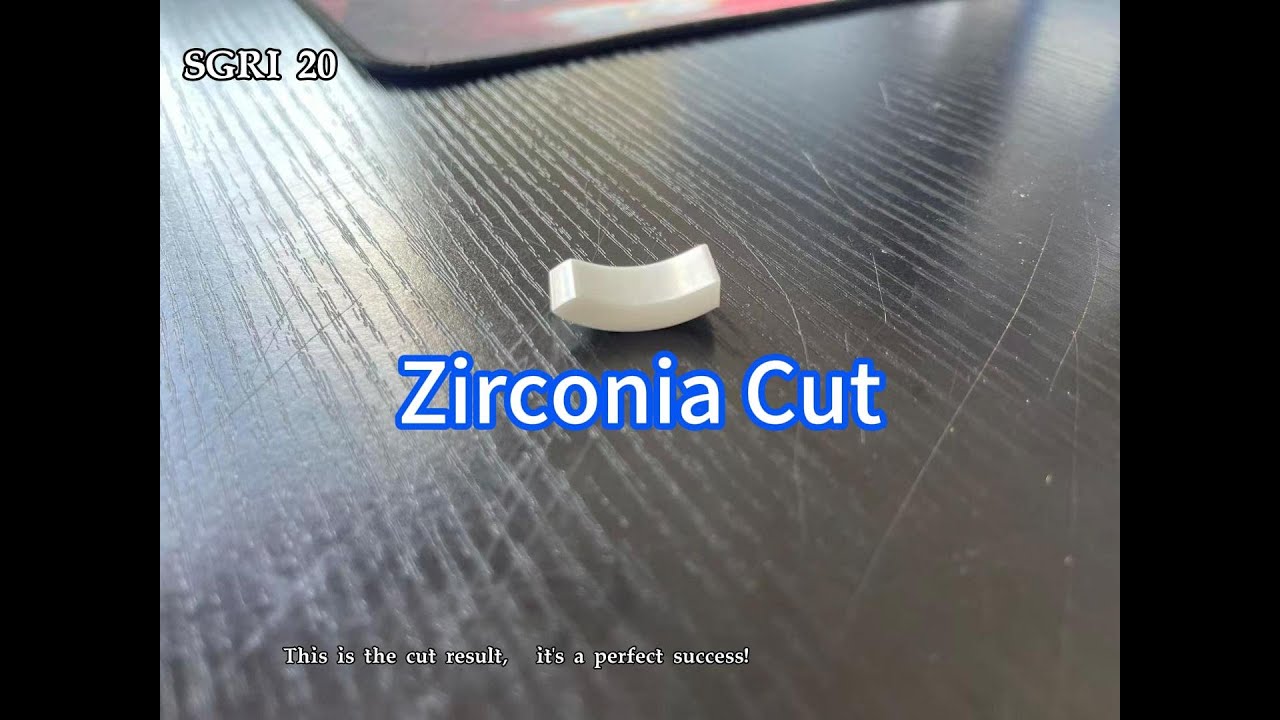

What makes this technology revolutionary for robotics is its ability to achieve sub-millimeter precision cuts even in dense ceramics like alumina, zirconia, and silicon nitride. These materials form the “bones” and “joints” of humanoid robots — parts that must endure mechanical load and friction without deformation.

The result? Components that are smoother, stronger, and far more consistent than those made with conventional sawing or milling methods.

3. Why Traditional Cutting Fails in Humanoid Manufacturing

Metal blades and CNC milling machines face fundamental limits when cutting ceramics. The tools wear out quickly, the process generates heat and vibration, and micro-fractures appear before the part is even assembled.

For humanoid robots — especially those designed for high-precision motion like robotic hands, knees, or facial mechanisms — even a 0.05 mm misalignment can cascade into mechanical noise or motion instability.

Diamond wire cutting solves this at its root.

Because it removes material abrasively rather than destructively, it reduces cutting stress and preserves the ceramic’s crystalline structure.

The narrow kerf width — often around 0.4 mm — also means less material loss and higher yield for expensive ceramic blanks.

4. From Silicon Wafers to Robot Joints: A Cross-Industry Evolution

The adoption of diamond wire cutting in robotics is part of a broader industrial convergence.

Techniques born in semiconductor wafer fabrication und Verarbeitung von optischem Glas are now migrating into mechanical design and robotics — a sign that precision manufacturing is dissolving boundaries between once-separate fields.

In the same way that microchips required ultraprecise silicon slicing, humanoid robots demand ultraprecise bone-joint geometry. Every curvature, groove, and pivot determines how the robot balances, walks, and interacts with the world.

And just as semiconductor manufacturing reshaped the electronics industry, diamond wire cutting could redefine the mechanical foundation of intelligent machines.

5. Toward the Future of “Soft Precision” Robotics

Paradoxically, the more humanlike robots become, the more they depend on rigid materials.

Behind every “soft” gesture of a humanoid lies a skeleton made of ultra-hard components — cut, shaped, and refined to perfection.

Diamond wire cutting gives designers the freedom to sculpt these components with the same precision seen in microelectronics.

It’s the bridge between the softness of motion and the hardness of matter — the reason why future humanoids will not just move gracefully but endure the test of time.

6. Conclusion: Precision Is the New Intelligence

As AI pushes robots toward humanlike cognition, materials and manufacturing precision are becoming the true differentiators.

No algorithm can compensate for poor mechanical alignment or surface roughness. The intelligence of future machines will depend as much on their physical craftsmanship as on their neural networks.

So while the world watches software evolve, the silent revolution might be happening elsewhere —

on the cutting line,

where Diamantdraht quietly sculpts the bones of tomorrow’s robots.

👉 Explore more about precision diamond wire cutting technologies at www.endlesswiresaw.com